close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-09-16 Origin: Site

Have you ever faced this situation: you turn on your water purifier in the morning, but the RO membrane produces no water; a factory production line halts due to water treatment equipment downtime, with urgent orders pending; or a hotel or school drinking water system suddenly “shuts down,” affecting hundreds of people? The problem of RO membrane not producing water not only disrupts daily water usage but may also lead to production losses for businesses and pose potential drinking water safety risks for households.

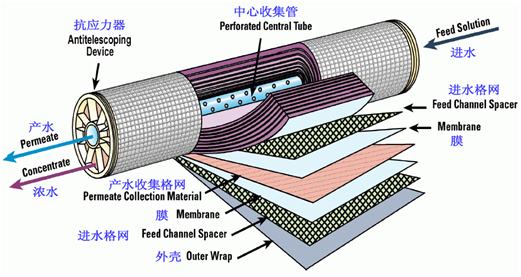

Figure 1: RO Membrane Structure Diagram

In RO membrane systems, the core cause of the “no water” issue is membrane fouling, primarily due to organic and inorganic contaminants. These fouling materials are not formed by a single factor; the main causes include:

1. Excessively High Recovery Rate

During RO operation, water molecules can quickly pass through the membrane, but solutes cannot. Solutes gradually accumulate on the concentrated side of the membrane, forming a concentration polarization layer—where the solute concentration is much higher than in the feed water. When the recovery rate is set too high, the residence time of feed water in the membrane module is prolonged. This increases the thickness and concentration difference of the concentration polarization layer, accelerating organic fouling and inorganic scaling, eventually causing blockage. Solution: Set a reasonable recovery rate during system design to avoid excessive concentration polarization.

2. Pre-treatment Failure

If pre-treatment components fail—such as clogged PP sediment filters not replaced, saturated activated carbon, or security filters allowing sand passage—impurities in the feed water enter the RO membrane directly. Over time, organic matter accumulates on the membrane surface, forming a dense organic fouling layer, blocking membrane pores and hindering water permeation. Inorganic salts, if not softened in pre-treatment, can precipitate as scale on the membrane surface due to concentration effects, further blocking the pores. Solution: Regularly inspect and maintain all pre-treatment components to ensure effective filtration and softening.

3. Feed Water Quality Issues

If feed water contains high levels of salts, cation-anion combinations may form insoluble crystals on the membrane surface or within pores, causing physical blockage. If feed water is rich in organics, adsorption or bridging effects can create dense organic fouling layers. When both high salts and high organics exist simultaneously, organic-inorganic composite fouling may occur, intensifying membrane blockage. Solution: Improve feed water quality through enhanced pre-treatment, precise operating parameters, and appropriate chemical dosing.

As a water treatment company with 28 years of experience, UMEK Environmental offers a complete set of solutions. We provide high-quality RO membranes suitable for residential, commercial, and industrial applications, and deliver full-process services: water quality testing → equipment selection → installation & commissioning → ongoing maintenance. Our systems have served thousands of enterprises and households, solving countless water treatment challenges with reliable performance and professional expertise.

If your RO membrane is not producing water, or if you want to proactively maintain your equipment and avoid future issues, contact UMEK today! Call our service hotline for a free one-on-one water analysis and troubleshooting advice, with exclusive purchasing offers available. Choosing a company with 28 years of experience means choosing worry-free, reliable water treatment.

Contact Information:

Tel: +86 19331305749

Email: sales@cnumek.com / sales@amandawatertech.com

Website: www.amandawatertech.com / www.cnumek.com

content is empty!